Undergraduate Projects

This section highlights the projects that I have worked on during my undergraduate studies.

Extra Curricular

HyTech Racing –Planetary Gearbox

Fall 2016-Spring 2017

I designed the planetary reduction system between an EMRAX 208 electric motor and the differential on the team’s entry 2016-2017 entry to the Formula SAE Electric competition. My design uses the planetary gears from a Ford 6L40 transmission along with a custom housing and axles. The design was validated with the SolidWorks FEA package and then CAMed with HSM works. The housing and axle were then machined in a Haas VMC.

This project was honestly the hardest things I ever worked on. Interfacing the Ford parts with my parts proved quite challenging, because simply a Ford transmissions were never meant to be worked into another gearbox, and it was stressful to design a housing that would see large torques, up to 480 Nm. In the end, the design did not work out, because the tolerances of the housing was a bit too loose, causing binding issues.

In retrospect, I approached this project a little too arrogantly and naively. I needed to ask for more help from my peers and industry experts rather than try to figure things out myself.

|

|---|

|

|

|

|

|

|

Class Projects

ECE 2811 –"Soft" Gripper

Fall 2016

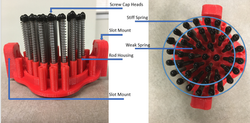

This class is a Vertically Integrated Projects (VIP) class. VIPs are multidisciplinary classes that bring students from different majors to work on a large project. For the project, the class sought to investigate the application of soft robotics to fruit picking. This semester was a continuation of the work done in Spring 2016 (see below) and sought to design a more novel soft gripper than last year’s. To achieve a unique gripper design, it was decided that the gripper would combine the best aspects of hard and soft robotics. The hard robotics formed the macrokinematics of the gripper, which provided the general gripping motion; the soft robotics formed the microkinematics, which interacts directly with the fruit. I worked on the microkinematics.

On the microkinematics team, I came up with a design that was based on the pinscreen toy and digital clay. A large number of sprung pins conform around a fruit, encapsulating it to provide a basis for gripping. To develop the gripper, I drew up more than 100 models in SolidWorks and made several of the models using 3D printers and laser cutters. Notable prototypes included urethane springs casted in 3D printed molds used to investigate different springs and balloon animal balloons used to explore the use of balloons for holding actuated pins in place.

In the end, an effective and simple fruit gripper was developed. Despite the early successes, more work is needed in order to improve spring compliance, explore pin geometries, and reevaluate braking (see video).

Results

-

A gripper for larger fruits such as apples and oranges, and a smaller gripper for picking fruits such as blueberries.

-

Both gripper sizes can pick up fruits of sizes from blueberries to apples.

-

Gripper made of 3D printed parts, hollow aluminum tubing, and rubber stops.

Deliverables

-

Final report cannot be shared, but the video details the design of the gripper.

Video providing an overview of the design process

|

|---|

|

|

|

|

|

ME 2110 Final Project –Black Widow

Summer 2016

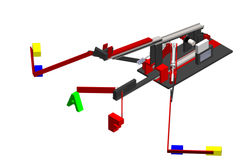

ME 2110 is the premier design class for Georgia Tech's mechanical engineering students. The class focusses on the engineering process with an emphasis on planning and report writing. For six weeks near the end of the course, students are divided into groups of four to develop a robot that competes in a competition among students. Students are evaluated on the quality of their prototyping, reports, presentation, and of course competition performance. For the competition that I competed in, the robot had to be designed to complete “The Georgia Tech Experience” by getting sleep, returning the T, and earning good grades; meaning that the robot had to gather pillows on the field, move a T-shaped block to the center of the field, and remove an F-shaped block and gather an A-shaped block.

For the competition, I served as the unofficial leader for my team. I guided much of the design discussion and planning for the team. In terms of the robot itself, I developed the T return mechanism, which was widely emulated among the class; and the pillow grabbing mechanism, which was the fastest mechanism in the class. In addition, I edited the reports and gave the final presentation. However, it is important to note that none of the mechanisms I developed were truly unique; I based them on ones that I have seen before. Furthermore, years of high school robotics gave me a large head start in mechanism design and the ideation process. Finally, my team played an invaluable role in the project. They troubleshot and improved the mechanisms that I designed, wrote significant portions of the reports and presentations, and of course built a good portion of the robot.

Robot Performance

-

#3 seed out of 28 entering the competition

-

Quarter final finish

-

3-1 win/loss record

-

Reporting

-

Wrote the report that was cited as an excellent report by the professor.

Deliverables

Video of Match 2, the best match of Black Widow. Black Widow scored 50 points, easily winning the match

|

|---|

|

|

|

|

|

ME-1770 Final Project –The Ramblin Rover

Spring 2016

ME 1770 is the engineering visualization class at Georgia Tech. The class was divided into two main portions: sketching and CAD (SolidWorks focus). For the final project, the professor divided the class into several groups of five. Each of the groups needed to CAD a complex assembly of a minimum of 50 different parts, 10 for each member. My group decided to make our own version of a Mars rover. It can fly.

I worked on the rocker bogie drive system of the rover. Taking inspiration from Curiosity’s drive system, I made several modifications to suit the needs of the project. The first of the differences is the use of spur gear differential instead of a differential bar linkage to connect the two sides of the drive system. This was done in order to simplify the integration of my subsystem to the rest of the rover. The second difference is the use of six steering modules instead of four. This was done in order to reduce the number of unique parts that needed to be designed. For my subsystem, I wanted to make my assemblies relatively detailed, because I wanted to better understand how a differential works and what components goes into a steering module.

CAD Models

-

117 unique components in the rover

-

47 unique components in the drive system

-

-

Modeled with robust modeling technique to allow for rapid iteration

Rover Features

-

Four rocket propulsion units to allow for rapid rover repositioning

-

Solar panels to avoid the hazards of nuclear batteries

-

Omni-directional drive system with suspension

Results

-

Earned the max points possible for the project

-

Deemed an example project by the professor

Deliverables

Animation of the rover

|

|---|

|

|

|

|

|

ECE-2811 Final Deliverable –“Sticky Fingers”

Spring 2016

Vertically Integrated Projects or VIPs are multidisciplinary classes that bring students from different majors to work on a large project. For my class, the class sought to investigate the application of soft robotics to fruit picking. The class was divided into three groups: kinematics, controls, and fruit ripeness. I worked on the kinematics team. The kinematics team was charged with coming up with and prototyping various gripper concepts. For the final deliverable, the kinematics team settled on the “sticky-fingers” concept which is a modification of the Pneu-Net concept. The modification is the addition of magnets to the tip of the fingers in order to get the fingers to close more securely. In addition, a plunger mechanism was added in order to better seat the fruit into the gripper.

For the final deliverable, I primarily worked on developing the SolidWorks models of the fingers in order to make the molds and provide the geometries for FEA analysis. In addition to the finger development, I developed the testing platform for the fingers. The testing platform allows the group to rapidly adjust the spacing and angular position of the fingers.

Results

-

Pneumatic gripper was able to securely grip an apple

-

Unable to achieve enough curvature to grip blueberries

-

-

Pneumatic gripper was able to pick an apple from below (i.e. from the tree)

-

Pneumatic gripper could be tilted 90 degrees from vertical and still hold the apple securely

-

Magnets kept the fingers closed even when pneumatic power is removed

-

Fingers were inconsistent in curvature due to poor elastomer mixture control

-

Manual control of the plunger gave inconsistent results

Deliverables

-

Unfortunately, I cannot share the final report.

The Sticky Fingers concept in action